|

To build a wooden IOM shell you will need planks, typically of either Balsa

(lighter, weaker, easier to work, but will need glass

sheathing, probably inside and out) or Wester Red Cedar

(still best to glass sheath, but not essential and thinner

glass possible). For most people best to pay a specialist

for the planks, cutting your own is very tricky. Mine

were actually "Brazilian Cedar", very pretty,

but a little heavier than Western Red Cedar.

|

| |

|

|

|

.JPG) |

| Planks should be at least 1100

mm long, ideally 10 mm wide and 3 mm deep. Slightly thinner

(2.7mm) is better, but hard to obtain.

Make a method of holding the planks so you can plane them.

I used bits of old venetian blinds 3 mm apart, and deeper

in the middle secured to a flat 1.3 metre piece of wood, held

in my vice . |

|

I also hold the plank with one hand while

planing with the other hand. The small block plane works well

for me. Modellers planes also good. Planks tend to be narrow

at the front and back depending on boat shape, and angled

on one edge. |

|

|

|

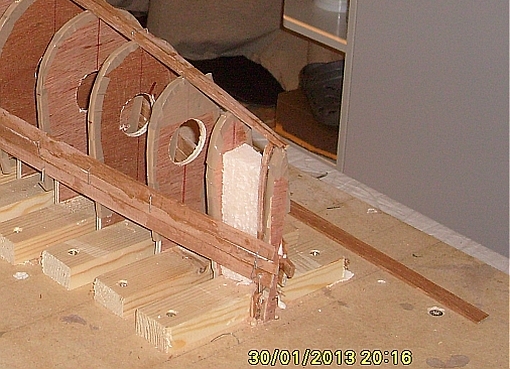

| My building frame is a piece

of 1" MDF, about 1.3 metres * 400 mm. I have a very straight

line drawn down the centre of this to align the (shadows /

sections (just a name, same thing), and because I choose to

have frames every 50 mm I marked off lines at rt angles to

the centre line every 50 mm, starting at the transom. Some

just have shadows every 100 mm. For me I made the shadws from

6 mm plywood, cut on a bandsaw and finished with spokeshave.

All shadows were traced from a set of full sized plans (in

my case from Ian Vickers V8 design). All have a centre line

and in this case the chines are pen marked on them. All are

glued to a piece of 11/2" *1" and screwed to the

board so they are exactly in the right place (from the widest

point of the boat aft the back of the shadows are exactly

on the lines across the board, and from the widest point forwards

the front of the shadow is on the line across) are and the

centre line is vertical, so the boat is straight. It is possible

to get laser cut shadows, more accurate than I can do. |

|

All shadows are covered in parcel tape where

the planks will touch en to stop they glueing to the shadows.

I started planking with 2 planks either side of the centre line,

so I have a perfect centre line for putting in keel case and

mast, frames etc. Planks are glued to each other, in my case

with "Titebond 111", a water resistant PVA. The bow

and transom shadows are a special case, where I have the actual

bow and transom in place, so no parcel tape, so the planks can

be glued to them. I also attached a false bow in front of the

real bow (see picture above) and a false transom behind the

true transom to help make the planking easier. In the case of

the V8, the bow is very fine, so it needs extra support as shown

with the foam between shadow 0.5 and the bow. The bow, transom

and false bow and transom need a bit of shaping to let the plank

fit flat on the frames.

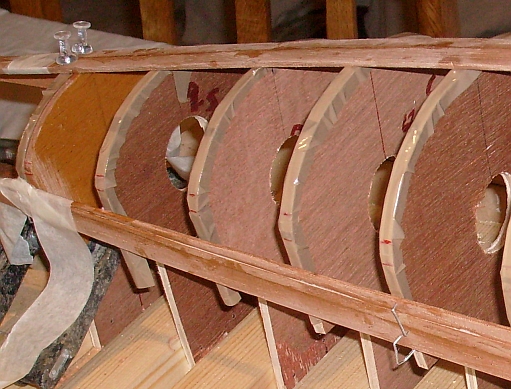

The next planks are on the gunwale line, helping steady the

boat sideways |

|

|

|

| I secured each plank with fine

staples or pins. This shell was actually a plug for a glass

fibre boat, so pin holes did not matter. With care, sticky

tape and small clamps and pins into the shadows but not throught

the plank you can glue each pair of planks without damaging

them. You will though only be able to work with 4 planks at

a time (2 on centre, 2 either side. Always work in pairs of

planks either side. |

|

Note that with the exception of the gunwale plank,

the planks are thinner at the transom and bow. No angles shaping

is needed on these planks as this boat has a slab sided topside,

whereas the centre line planks do need angled shaping. |

|

|

|

| With the bow being so fine, the planks

can easily pull the bow off centre, hence the string while glue

is setting. |

|

Note always working in pairs of planks. The

chine was a particular case where lots of angled shaping was

needed. I run all planks the full length, but this is not

necessary, and you can for example have a long scarf like

join at the chine. This will allow for less narrowing of the

planks. |

|

|

|

| Last 3 planks to go in each side. |

|

All planked up. Note the planks run beyonde

the bow and transom at this stage |

|

|

|

| Time to pull out the staples. |

|

|

|

|

|

| Planks sanded with long board with

Aluminium oxide abrasive paper. Bow and transom trimmed off

(but still over sized because of the false bow and transom).

Note the pin holes are almost impossible to see and fill with

wood dust if you are lucky. |

|

I epoxied and sheathed the shell with 40 gram

glass fibre for extra strength and protection. The stripes

you see above is in fact peel ply which is put on top of the

glass when wet. This helps soak up any excess resin. You later

pull that off, and it leaves a surface that you can sand easily

without damging the glass much, again sanding at least initially

with a long board. |

|

|

|

| I made this cradle (external set

of 4 frames cutout to to the outside shape of hte hull at specific

locations). This allows the boat to be placed in the cradle

and keep a comparatively accurate shape |

|

Undo the shadows from the board, remove each

shadow leaving just the bow and transom to help it keep an

accurate shape. Put at least one temporary bulkhead in place

roughly mid-length to stop the boat growing thinner and longer

(not show here). I then glued 2 planks (one either side) to

the inside of the gunwale, with the top a few millimetres

above the existing gunwale to help re-enforce the gunwale

allowing for hull to deck joint. I used clothes pegs as clamps. |

| |

|

Next page |