| |

|

|

|

|

| |

It is important to have

a good frame to make sure the boat keeps its shape., though

perhaps this is a bit overkill. |

|

Shell secured in frame.

If the frame is accurate enough, you could secure with double

sided tape. |

|

| |

|

|

|

|

| |

Having checked measurements,

epoxy (with silica powder) in transom. I prefer an inset transom,

it allows you to get the length exactly right, and you can put

a fillet radius both sides for strength. |

|

Do the same for the bow |

|

| |

|

|

|

|

| |

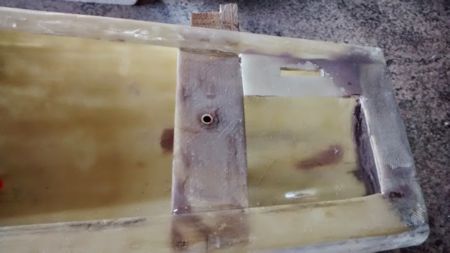

Fit main bulkhead &

glue, as for the bulkhead that supports the jib swivel points.

Then when dry, secure the keel case |

|

One of our group devised

an accurate methof of aligning the keel case. Sadly my boat

was already built. |

|

| |

|

|

|

|

| |

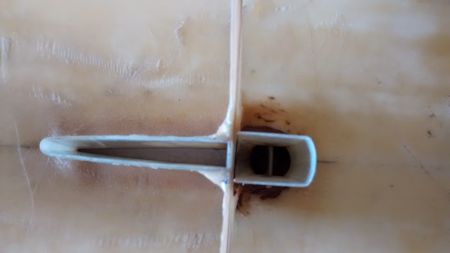

From sheet glass, make

and fit strut to floor to support jib swivel, and mainsheet

tube and support, as well as rudder tube and under deck re-enforcing

for rudder upper bearing |

|

Winch and rudder servo

bonded in place, using the mast tube to support it. |

|

| |

|

|

|

|

| |

The mast tube in this

boat is fixed in front of the bulkhead in order to keep the

keel and mast very close |

|

Mast tube glued in. It

is extremely hard to get exactly right, and this one was removed

and re-positioned / glued the same day (but no photo) |

|

| |

|

|

|

|

| |

Extra strengthening for

Rudder. The tube you can see here is the top bearing. Below

is a gap for the tiller, then the rudder stock tube is below

that and out the bottom of the boat |

|

Underside of foredeck.

not the channel to attach to the "strut" that goes

down to the floor. The deck eyes are already in, as are the

jib sheeting loops. |

|

| |

|

|

Sorry, no photo |

|

| |

Make sure the well touches

the keel case and in our case the bulkhead. The one shown about

shows a small gap at the top back of hte case which is sorted

later. |

|

Using epoxy resin with

thickening powder (collodial silica) glue on first stern deck

and late foredeck. I appear to have no photos, hands too sticky? |

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

Sand and paint boat.

I started with hibuild epoxy all over, and eventually finished

with cheap spray paint. |

|

In 2 colours. I did have

to re-paint later as some in the club objected to my painting

skills! |

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

this layout had all the winches / servos /

batteries in the pot. As it turned out, a good idea but it

was difficult to change winches, which at that stage I bust

with worrying frequency |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|